Expanded Polypropylene (EPP); It is a closed-cell foam material that offers unique features such as superior energy absorption, multiple impact resistance, thermal insulation, resistance to water and chemicals, extremely high strength compared to its weight and being 100% recyclable. EPP products can be produced in densities between 18 – 260 g/l. EPP beads are formed into the final product form by the steam molding process.

History of EPP

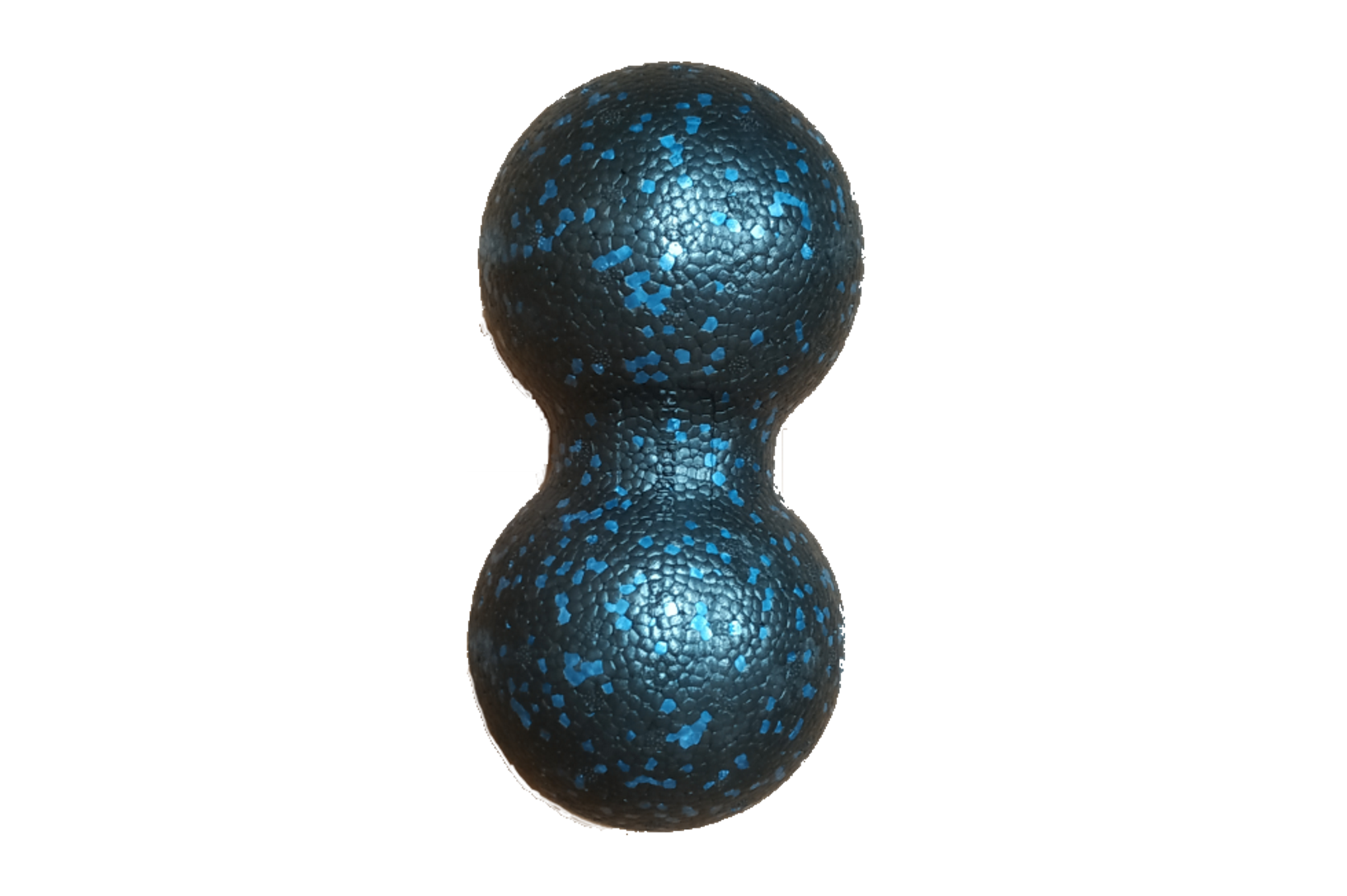

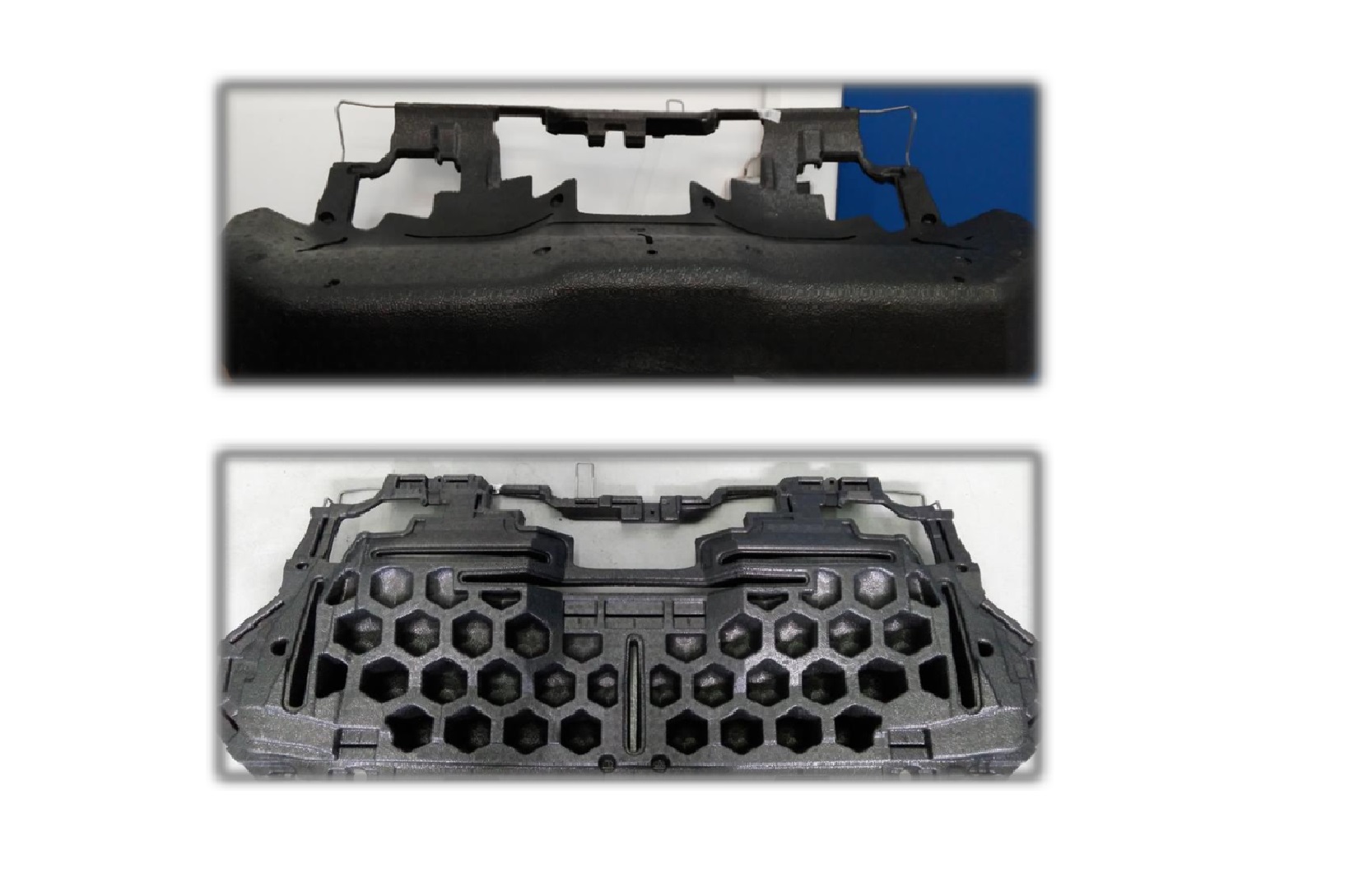

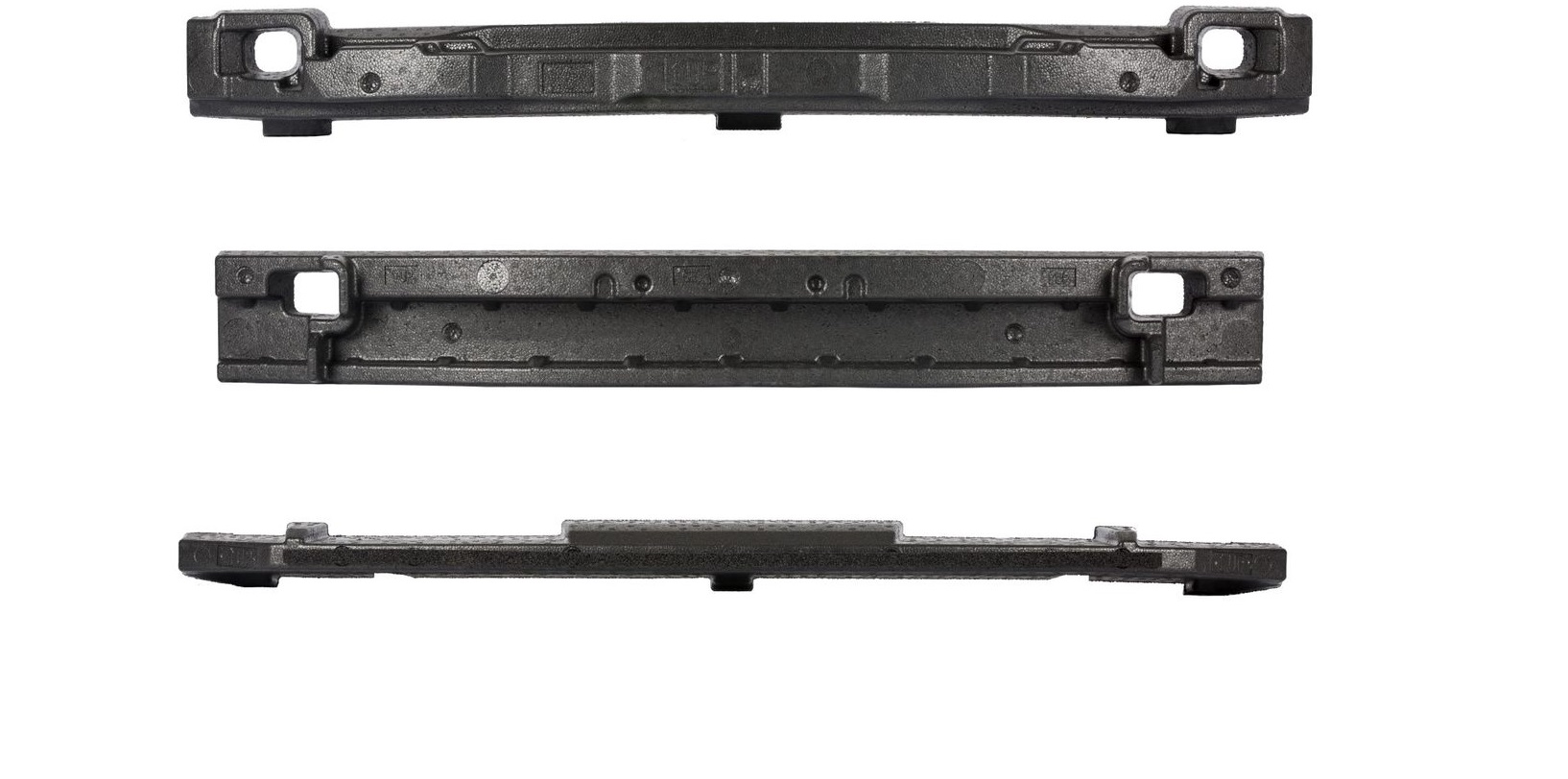

EPP was first developed by the company JSP in the 1970s as a result of the search for new forms of polypropylene. The first applications of this material were used for automotive products in Japan in 1982. Demand for EPP has grown significantly in all regions of the world since then, based on the need for automakers to improve their energy management functions while improving weight reduction and environmental benefits. The first automotive application for EPP was as an energy-absorbing component in bumper systems. EPP is now widely used in automotive parts and systems, including seat assembly and other interior components. Non-automotive uses of EPP are constantly being developed by companies such as Atermit. Examples are frequently encountered in business lines where light and robust products are used, such as HVAC (Heating, Cooling and Ventilation), furniture, transport boxes, sports equipment.

Lightness

PP is used in the automobile industry to increase vehicle safety and make vehicles lighter. It reduces the weight of seat systems by up to 10 kg. Lightness reduces fuel consumption and exhaust emissions in cars, because for every 100 kg of vehicle mass increased, the CO2 output increases by 10 g/km.

Structural Strength

– EPP offers a very high strength to weight ratio with load bearing structural support in many applications. EPP can carry substantial loads with little loss in form or shape.

Energy Dissipation

EPP is an excellent energy-absorbing material, resistant to multiple impacts, without deformation. Its light weight and exceptionally high strength-to-weight ratio make it a good choice for applications such as vehicle crash protection components. High density EPP can be used as an energy absorber for even the heaviest industrial applications.

Recycle

– EPP is an environmentally friendly, 100% recyclable “green/green” material. VOC (Volatile Organic Compounds), chlorofluoro carbon or other compounds that are considered harmful to the environment are not used in EPP during the manufacturing process. EPP can also be used in finished products with a certain amount of crushing.

Thermal insulation

– EPP provides excellent thermal insulation for applications where food, medical supplies and other temperature sensitive products need to be protected. EPP’s superior thermal insulation properties, combined with key features such as flexibility and easy mouldability, make it ideal for use in Heating/Cooling/Air Conditioning applications.

Acoustic Insulation

– Provides acoustic improvement in components used in EPP vehicles. In many other applications it also reduces noise levels as a motor housing; however, it reduces the weight of the devices, increases the maneuverability and protects against accidental impacts.

Chemical Resistance

– EPP; It is resistant to many chemicals such as Automotive Fluids, Hydrocarbons, Chlorofluorocarbons, Ketones, Esters, Alcohols, Alkalis, Inorganic Acids.